Exactly how to Keep and Adjust Your Industrial Scales Properly

Exactly how to Keep and Adjust Your Industrial Scales Properly

Blog Article

Just How Industrial Scales Improve Accuracy in Production and Logistics

By making certain that products are considered properly, organizations can reduce mistakes that can lead to substantial financial repercussions. The development of innovative technologies in evaluating systems is changing conventional processes.

Value of Accuracy in Procedures

In the world of production and logistics, precision is the keystone of functional performance. Exact measurements are crucial for maintaining quality assurance, enhancing source allocation, and ensuring compliance with industry requirements. When procedures count on specific data, organizations can decrease waste, enhance manufacturing timelines, and enhance overall productivity.

The significance of precision extends past easy dimension; it likewise affects decision-making processes. For example, accurate weight analyses can figure out appropriate stock degrees, simplify supply chain logistics, and help with exact invoicing. Furthermore, mistakes in measurements can result in pricey errors, such as overflow or ignoring product needs, which can threaten project timelines and profitability.

Furthermore, precision in procedures promotes a society of liability and quality control. By executing extensive dimension criteria, companies can recognize inefficiencies and enact enhancements, eventually causing boosted customer fulfillment. In a period where competitors is fierce, the capability to provide services and products with precision can be a distinct factor that establishes a firm apart. Hence, purchasing accuracy measurement devices, such as industrial ranges, is not merely a technical factor to consider however a strategic critical for success in the manufacturing and logistics industries.

Types of Industrial Scales

Different kinds of commercial ranges play a crucial function in accomplishing the precision required for efficient production and logistics procedures. Each kind is created to meet particular demands, making sure accurate dimension of materials, items, and elements.

One typical kind is the system scale, which offers a level surface area for weighing bulk materials or big things. Another type is the bench scale, commonly smaller and utilized for considering individual plans or smaller sets of products.

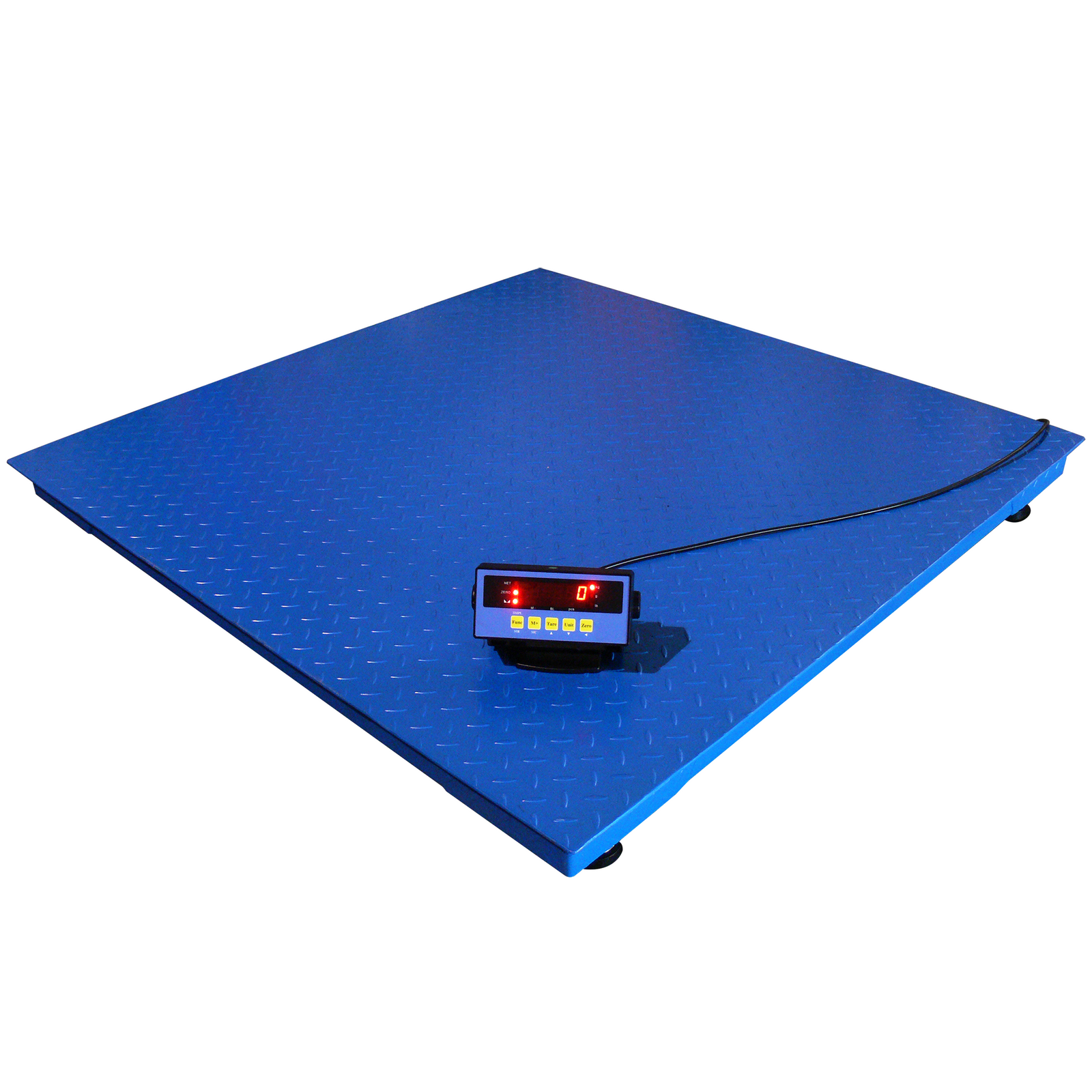

For applications where accuracy is important, analytical equilibriums are employed. These high-accuracy ranges are used in research laboratories and research setups to measure tiny amounts with utmost precision. Floor ranges, designed for heavy-duty evaluating, are perfect for considering big pallets or containers, frequently integrated with forklifts for efficiency.

On top of that, tons cells are utilized in different applications for real-time weight dimension and information collection. Each of these scales adds distinctively to the functional effectiveness, guaranteeing that companies can maintain precision throughout their manufacturing and logistics procedures. Comprehending the sorts of commercial scales is necessary for optimizing efficiency and achieving functional quality.

Influence On Supply Monitoring

Precise weighing is essential for effective supply monitoring, as it straight affects supply precision and functional efficiency. In manufacturing and logistics, accurate measurement of items and materials guarantees that stock documents reflect actual supply degrees, lowering discrepancies that can result in overstocking or stockouts. Industrial scales provide the required accuracy to consider items accurately, enabling companies to visit site keep a dependable supply system.

Additionally, exact considering adds to much better projecting and preparation. With precise information on inventory levels, companies can make enlightened choices relating to procurement and production routines. This decreases the threat of excess inventory, which can bind capital and boost storage prices, as well as protect against lacks that might disrupt procedures.

Furthermore, the integration of commercial ranges with stock management systems promotes real-time monitoring of stock movements. This streamlines the procedure of upgrading inventory records, boosting transparency and responsibility throughout the supply chain. Ultimately, exact considering not only supports reliable inventory management yet additionally drives total functional efficiency, enabling organizations to respond swiftly to market demands and keep an one-upmanship in their corresponding markets.

Enhancing High Quality Control

Effective inventory administration not only ensures optimal supply degrees but also lays the groundwork for durable top quality control procedures. Industrial ranges play an essential role in improving quality assurance by giving accurate weight dimensions that are crucial for preserving item stability. Consistent weight confirmation allows manufacturers to comply with specifications, making certain that each product satisfies the required high quality standards.

In high-stakes atmospheres, such as food production or drugs, even minor weight disparities can lead to considerable conformity concerns. By integrating industrial scales into the assembly line, companies can keep an eye on item weights in real time, enabling prompt corrective actions if problems are discovered. This aggressive try this website method decreases waste and improves total product reliability.

Additionally, exact evaluating promotes much better solution of raw materials, which is critical in industries like cosmetics and chemicals. By guaranteeing that component proportions continue to be regular, manufacturers can accomplish exceptional product high quality, enhancing client fulfillment and minimizing returns.

Future Patterns in Evaluating Innovation

The future of weighing technology is poised for substantial advancements driven by automation, connection, and information analytics. As sectors evolve, the integration of advanced sensing units and IoT (Net of Points) abilities will enable real-time surveillance and coverage of weight information. This connection will not only improve operational effectiveness however likewise help with predictive maintenance, lowering downtime and boosting efficiency.

Additionally, the incorporation of expert system and artificial intelligence formulas into weighing systems will certainly enhance information evaluation abilities. These innovations can identify patterns and abnormalities, permitting more informed decision-making and maximized supply chain administration. In addition, the surge of cloud-based services will certainly enable seamless information sharing across systems, guaranteeing that stakeholders have accessibility to updated information in any way times.

Sustainability will certainly also play a critical role in future evaluating technology. As companies make every effort to reduce their carbon impact, weighing systems that include energy-efficient designs and materials will certainly end up being increasingly vital. In addition, improvements in digital evaluating ranges will support better resource management by offering exact dimensions that minimize waste.

Verdict

In verdict, commercial ranges dramatically enhance precision in production and logistics by giving precise weight dimensions essential for efficient procedures. Their duty in supply monitoring, quality assurance, and combination with advanced technologies underscores their significance in lessening inconsistencies and enhancing resource allotment. As industries remain to progress, the fostering of ingenious considering remedies will even visit this website more sustain operational performance and minimize waste, eventually adding to improved productivity and competition in the marketplace.

One common type is the system scale, which provides a level surface for considering big items or bulk products. Another kind is the bench scale, typically smaller sized and used for considering private plans or smaller sets of products. Flooring scales, designed for durable weighing, are excellent for evaluating huge pallets or containers, typically incorporated with forklifts for effectiveness.

Industrial scales give the required accuracy to evaluate things accurately, making it possible for companies to keep a trustworthy inventory system.

Report this page